Solution

Influence Factors Of Laser Cutting

Influence Factors Of Laser Cutting

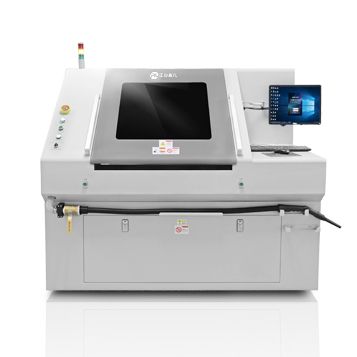

In Laser Processing Equipment of the Laser Cutting Machine China,laser cutting is one of the most important application of technology, sales of laser cutting machine in our country about 3000 units in 2015, laser cutting machine substitution effect in the shearing machine, punching machine is more and more obvious, the market at present is relatively popular after the application of laser marking, expected high cutting speed, high precision, large thick plates and cutting the high-end high-power laser cutting machine with the characteristics of wide equipment market has a larger growth space.

Influence factors of laser cutting processing shared by 3D Laser Cutting Machine Exporter.

In laser cutting processing, laser collimation of laser by cutting head and the focusing lens up to a point (focus), operators need to ensure that the processing of laser beam in the nozzle is the center, and adjust the nozzle spacing distance on the surface of the plate (depending on the thickness), the nozzle jet high pressure gas, and the laser beam to cooperate to complete cutting operation. The main influencing factors are as follows:

(1) focal diameter

Small diameter, narrow incision, small cutting thickness; Large diameter, wide incision, large cutting thickness.

(2) focus position

Determine the size of the workpiece surface spot and the shape of the cut; The best location depends on the type and thickness of the material.

(3) power

Affect the thickness of the cutting sheet; Affect machining efficiency and deformation.

(4) cutting speed

Need to match with power, gas flow, etc., too small will lead to the formation of impenetrable cutting or burr.

(5) nozzle diameter

Small diameter, suitable for sheet cutting; Large diameter, suitable for thick plate cutting.

(6) gas

The purity of gas affects burr formation and cutting surface oxidation. Gas flow, the thinner the plate, the greater the pressure.

(7) beam mode

Single mode has good effect in thin plate cutting, large multi-mode spot, uniform energy distribution, suitable for thick plate cutting.