Solution

The Small Hole Has A Big Emphasis on The PCB Board Drilling Test

As a PCB Hole Inspection Machine listed company, we want to tell you In the PCB drilling process, it is necessary to mainly control the following quality problems that may occur: porous, leaking, displacement, wrong drilling, impervious, hole loss, partial waste, batch peak, plug hole. At present, the control methods of various manufacturers are mainly the operation technology of the drilling rig before drilling and the strengthening inspection methods after drilling. However, in the actual production process, since the pre-drilling method can only reduce the probability of error occurrence, it cannot be completely eliminated, and it is necessary to rely on post-drilling inspection to ensure product quality.

In the post-drilling inspection, many domestic manufacturers are still using the plug gauge and the manual visual film (film) check-in comparison method. This method can theoretically detect various defects, but the effect is greatly discounted in practical use. .

Inspection requirements for small size apertures are not guaranteed;Manual inspection is inefficient;

The stability of quality cannot be guaranteed;

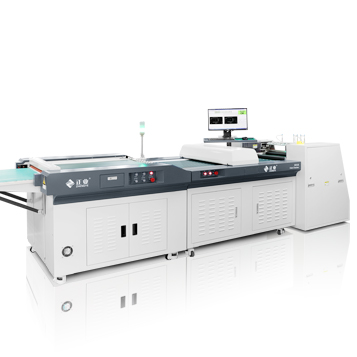

In order to solve the above problems, Zhengye has specially launched a high-quality PCB hole inspection machine to effectively improve the quality of the drilling and the final product quality. If you are interested in our products, please feel free to contact us!