Solution

Printed Circuit Board Quality Detection, There is Good Technology PCB Automatic Detection Production Line is Enough!

A small printed circuit board, hiding a great knowledge. Printed circuit board from production to be put into use, the middle is essential to detect the quality of circuit board, how to judge whether PCB quality qualified, we need to see if its size thickness conform to the standard, the appearance is neat and clean no deformation, line width, line spacing is in line with the requirements, etc., quality excellent circuit board can better improve the stability and safety of electronic products.

Therefore, the quality of printed circuit board detection is very important.

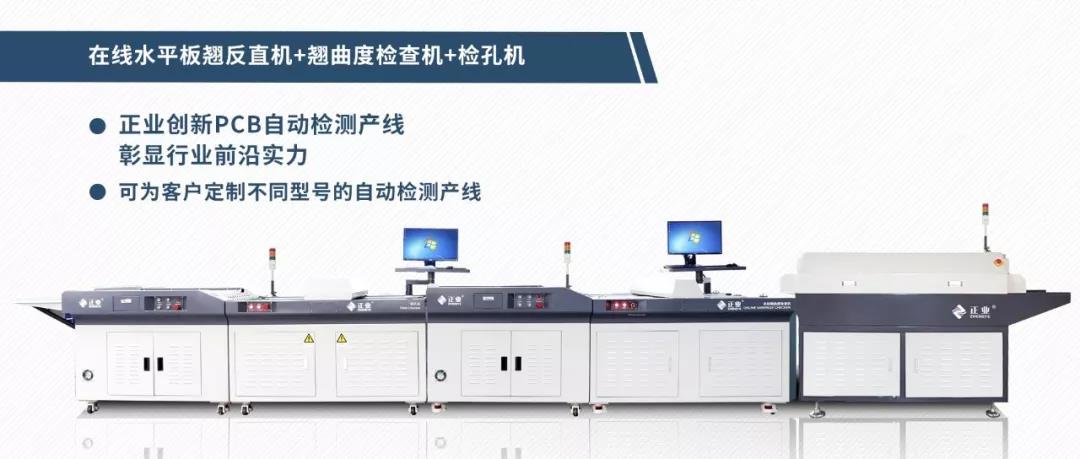

Take a look at the technology PCB automatic detection production line!

Decomposition of production line equipment:

Online horizontal plate warping and anti-straightening machine: PCB finished plate "plate bending, plate warping, deformation" rapid leveling.

Warping machine: PCB finished sheet or copper clad sheet "bending, warping, deformation" defects for quality inspection and analysis of warping value.

Hole Checker: drilling quality inspection and analysis of PCB drilling board and finished product board.

Their respective roles:

Skip the straight machine: online level can be automatic leveling for PCB product adopts infrared heating up and down, quickly will products are heated to high temperatures, of the finished plate by mechanical roller pressure, will bend and warp distortion () with positive force to achieve the effect of leveling, natural cooling and fan, won't cause secondary plate bending plate become warped.

Warp degree of inspection machine: for PCB finished plate or copper clad plate bending plate become warped deformation defects such as automatic detection, and based on the PCB board become warped, flatness standard: for surface mount components, such as SMT SMT, PCB its distortion and lay standard is not greater than 0.75% or 0.5%) were calculated, automatically determine NG/OK, at the same time.

Hole inspection machine: it can detect hole number, hole diameter and hole quality (such as hole, foreign body, slot length, slot short, etc.) of PCB after drilling and before packing, and automatically make OK/NG judgment, and classify at the same time.

PCB automatic detection production line can be operated automatically under the condition of no intervention, which can free people from the heavy manual labor and part of brain work, and make the production achieve "stability, accuracy and speed".

The working process

PCB automatic detection of production line advantages

Using PCB to detect production line automatically in mass production can improve productivity, reduce production cost, shorten production cycle, stabilize and improve product quality, and significantly improve economic efficiency.