Solution

Fully Automatic High Precision PSA Placement Machine

For a long period, the manufacturers of SMT machines occupying the leading position in the domestic SMT industry are foreign brands, including Panasonic, Siemens, Fujitsu, JUKI, Universal, Yamaha, and etc. China SMT technology started late and at a low level, and compared to the international top, there is a certain gap in technology. However, in recent years, with the breakthrough of domestic visual identification technology and sensor technology and the development of automated production lines, SMT automation equipment has been unable to meet the production needs. Complying with industry needs, Zhengye Technology Co., Ltd. in the intelligent manufacturing field with great concentration of research and development, launched a PSA automatic mounter to replace the worker who label PSA by hands.

Zhengye PSA automatic placement machine is located in the latter stage of the assembly process of the rigid and flexible circuit board. During the assembly process, the PSA auxiliary adhesive tape (PSA film, label, PI, etc.) on the feeder is sucked through the vacuum suction head and visualized by CCD. The fully automatic on-line placement equipment that is attached to the product after correction.

It can also be applied to paste paper, film and PSA in 3C industry with high speed and high precision. And it is the one of the most important equipment in entire SMT production.

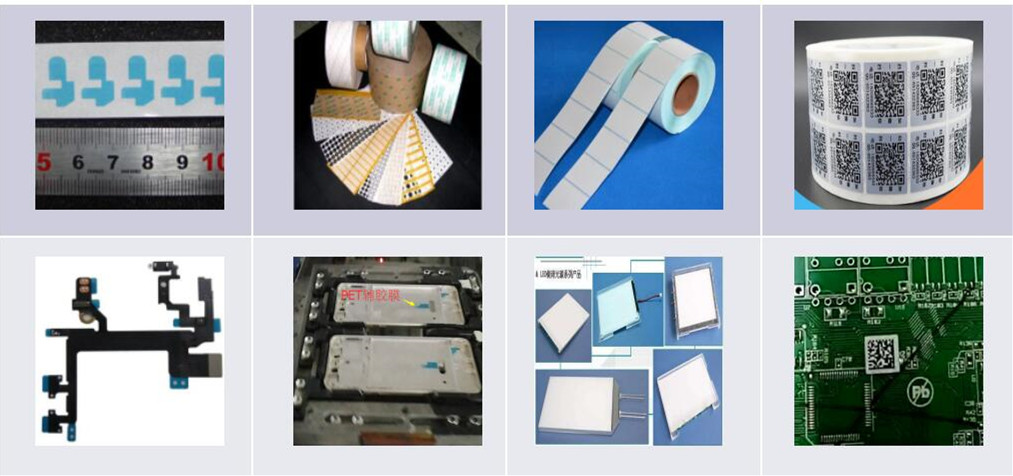

Samples are as following:

(case show from left to right respectively are: plastic sensitive adhesive (PSA), phone back cover auxiliary glue , LCD backlight , QR code label .)

Zhengye PSA automatic placement machine highlights:

◆ High efficiency

3600pcs/h, an industry advantage

◆ High precision

±0.1mm for precise fit

◆ Intelligent

It can link MES system to realize SMT online intelligent manufacturing

◆ QR code label printing

It can be used for sticking variable data QR code labels, applicable for material traceability production line

Zhengye PSA automatic placement machine focus on intelligent manufacturing "high-precision fit" field in order to solve the problem of market fit process flatness, stability, precision and other issues, to meet the foil, stickers, labeling, patch and other PSA auxiliary materials posted. It meets needs, replaces labor, reduces dependence on workers and realizes automatic docking. It is easy to operate, and is highly efficient and accurate, helping companies significantly increase production efficiency and promote the intelligent transformation and upgrading of traditional manufacturing industries.