Solution

Daily Inspection of Laser Cutting Machine

a. Before daily startup, carefully check the laser working gas and cutting gas pressure conditions, if the gas pressure is not enough, should be promptly replaced.

b. Check X-axis zero point, Y-axis zero point, Z-axis zero point, laser ready state button for damage, (check the indicator light).

c. Check the zero point of X axis, Y axis and Z axis, whether there is any looseness of the limit switch and the stopper mounting screw, and whether the limit switch of each axis is sensitive or not.

d. Check the chiller inside the circulating water level is enough, if less than must be added in time.

e. Check the external light circuit circulating water leaks, leaks must be promptly handled, or affect the life of optical lenses.

f. Daily cutting is complete, check the focus lens for damage.

g. Check the outer light path telescopic skin is burned or damaged.

h. Daily work is completed, the timely removal of cutting waste, clean the job site, keep the job site neat and clean. At the same time do a good job cleaning equipment to ensure that parts of the equipment clean and no dirt, the equipment can not be placed in all parts of debris.

j. After the daily work is completed, open the drain valve of the air reservoir at the bottom of the air compressor to drain it, and close the drain valve after draining the waste water.

k. After the daily work is completed, according to the shutdown step to shut down, and then turn off the entire power supply of the machine.

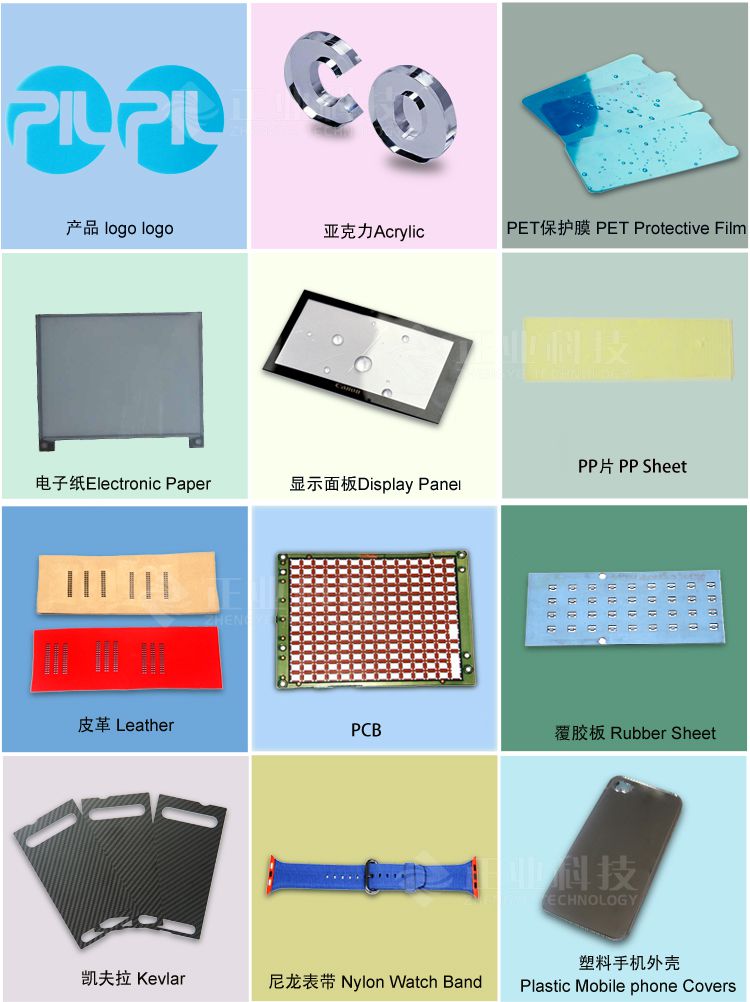

Recommended product:

High Speed CO2 Laser Film-cutting Machine sample :