Solution

UV Laser Cutting Application on Glass Scribing And Drilling

Glass is a brittle material, the processing process vulnerable to the impact of external forces and fragmentation, mechanical stress, heat influence can make the glass fragmentation, so the glass material processing process requires high precision, and in some high-end applications are even Will be used after stress testing. So in some high-end glass applications, glass processing are used in what way? This article is for everyone to announce the glass crossed, drilling applications.

The characteristics of UV laser cutting machine

UV laser cutting machine using cold light source of the UV laser, small spot, heat affected area is small, non-contact processing without mechanical stress, processing speed. The disadvantage is that the thicker glass is drilled, the UV light is taper, that is, drilling above the surface, small surface is small, and the processing thickness is low.

In the case of a biological reagent glass scribing and drilling, for example, the surface of such a glass is usually subjected to a wool treatment, and the treated surface is better treated by UV laser focusing on the surface, and the surface without the treatment More rough.

UV laser cutting machine on the glass crossed the effect is ideal, compared with the mechanical processing, the machined surface is more smooth, but in the amplification effect, the mechanical processing of the collapse of a significant larger.

UV laser cutting machine on the glass crossed, drilling and mechanical processing methods compared to enlarge the processing and surface contrast can be seen on the size of the control of the collapse, the UV laser processing is better than the mechanical processing. Single from the surface of the smoothness of view, the laser filling method is slightly worse than the mechanical processing.

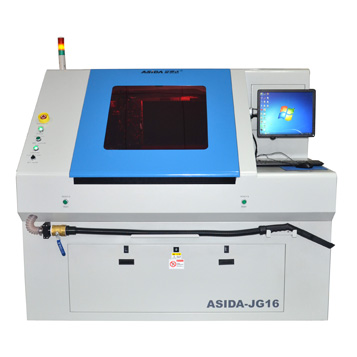

Recommended products:

UV Laser Drilling Machine JG23

More related products pls visit here.

In contrast, UV laser cutting machine processing glass, the biggest advantage compared with the machining process is the processing speed, the need for mechanical processing through the water to cool, rinse, in bio-glass applications, drilling and scribing need to be processed separately Laser does not need such a device, one-time molding, fast, small collapse, no stress, heat influence is small, this is the UV laser cutting machine cutting glass the biggest advantage.