Solution

Laser Cutting Machine Requirements for Processing Area

Laser cutting machine has requirements for processing areas. Generally speaking, the ground should be flat. The ground’s flat level directly affects the precision and speed of processing.Secondly, its processing areas generally are not allowed to have too much dust. Excessive amount of dust will not only affect the operator body and visibility. Laser cutting machine equipment space requirements to ensure the smokeless dust-free. In terms of temperature, general requirement is to load the air conditioning, because of the laser cutting machine in the process of processing work, especially in high power laser cutting machine, the high heat go out from the body. To the continuation of machining process and laser cutting machine, there must be a stable indoor temperature. Finally, laser cutting machine work is strict with the quality of the water cooling circulating water, requires the use of pure water, deionized water or distilled water, such as water. Pay attention that it can not use tap water, mineral water containing high metal ions or other minerals such as water, the water quality of laser cutting machine temperature cooling is of great influence.

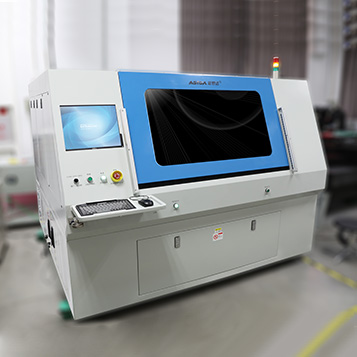

We provide Pico Laser Cutting Machine, which is mainly used for cover layer (CVL) cutting, flexible board (FPC) outline cutting, rigid-flexible circuit board (RF) cutting ,and thin multi -layer board cutting, as well as ceramics, silicon, aluminum foil, teflon, display glass etc..