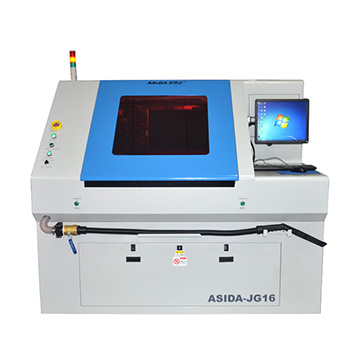

Solution

Application of LED Ceramic Substrate Laser Cutting Machine in Lamp Manufacturing

With the development and expansion of the national economy, people's living standards improved, the automobile industry developed. In the automotive accessories manufacturing industry, the more popular ceramic substrates have good thermal and electrical properties, is the excellent materials of power LED package, it is very suitable for multi-chip and substrate direct bonding chip package structure; Its excellent performance has become a high quality material for automotive LED ceramic substrates.

For cutting the LDE ceramic substrate requires sufficient power to cut the edge of the LED ceramic substrate laser cutting machine, compared to the physical cutting has better efficiency and yield. The use of LED ceramic substrate laser cutting machine cutting ceramic substrate in the automotive lamp manufacturing industry has the following advantages:

1. circuit board high frequency loss is small, can be high-frequency circuit design and assembly;

2. Ceramic substrate solderability are good, temperature range is wide;

3. Does not contain organic ingredients, high reliability, long service life;

4. Good surface insulation;

5. Smooth surface, no burrs, easy assembly.