Solution

Repair Techniques for Picosecond Laser Cutting Machine

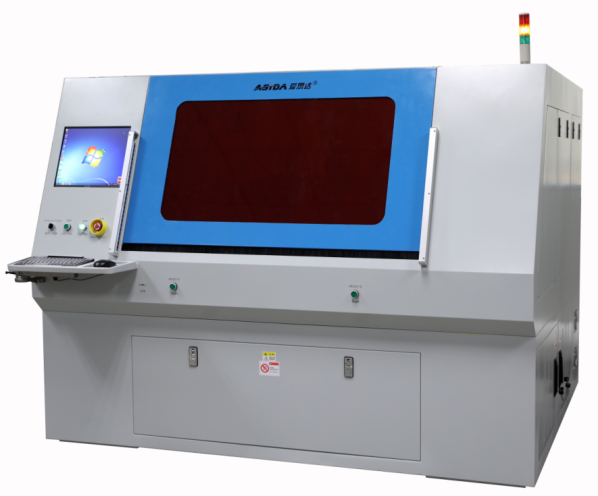

Picosecond laser cutting machine is a high precision, expensive equipment, good operation make the follow-up work more efficient, but also reduce costs. How to maintain high precision picosecond several cutting machine to ensure good health status?

1.Picosecond laser cutting machine current should be reasonable, can not be long-term work in full power; Rationally use laser and save laser energy; The optical system should be cleaned regularly; According to the material to adjust the working speed, keep the best working state of the laser tube.

2.Water cycle system often check the cleaning, cooling water often can not protect the float switch or water protection float switch, can not use short circuit to solve the problem. Cooling system should be grounded, often cleaning the water tank, cooling tank temperature should be appropriate. Check the circulating water level in the chiller is sufficient, if not enough to be added in time.

3.Ventilation system regularly check and clean, before stating the machine, carefully check the laser working gas and cutting gas pressure, if the gas pressure is not enough, should be replaced.

4.The working environment of the equipment can not be too bad, suspend work according to the situation.

5.After the completion of bulk cutting, should promptly clean up the cutting waste, clean the work site, keep the work site neat and clean. At the same time do a good job cleaning equipment to ensure that all parts clean, equipment parts can not be placed debris.