Solution

The New Clean Cutting Program

At present, the domestic semi-cured film cutting way mainly through pure mechanical cutting equipment, but this pure mechanical cutting process there are two aspects of quality and environmental defects:

First, the edge of the cloth at the edge of the glass cloth is easy to pull out, spread out, the formation of fluff, resulting in poor quality of the edge of the incision, a direct impact on the post-processing quality of prepreg. Second, the edge of the incision will be due to the role of mechanical and white layer, resulting in many broken small resin and glass fiber dust, does not meet environmental requirements, seriously endangering the health of employees.

Guangdong Zhengye Technology Co., Ltd. proposed a new clean method, combined with the characteristics of semi-cured film itself, the use of infrared heating principle of cutting, the semi-cured film cutting edge neatly, not powder, not on the curing sheet itself Material changes have any effect. Can be expected, pure mechanical processing, such as cutting the prepreg, is bound to lag behind, become a major obstacle to the development of technology, will lose the competitive advantage of the future market.

At this time, the need for semi-cured film cutting technology to upgrade, select the future development trend, leading one step ahead, leading the industry to a higher level of development technology.

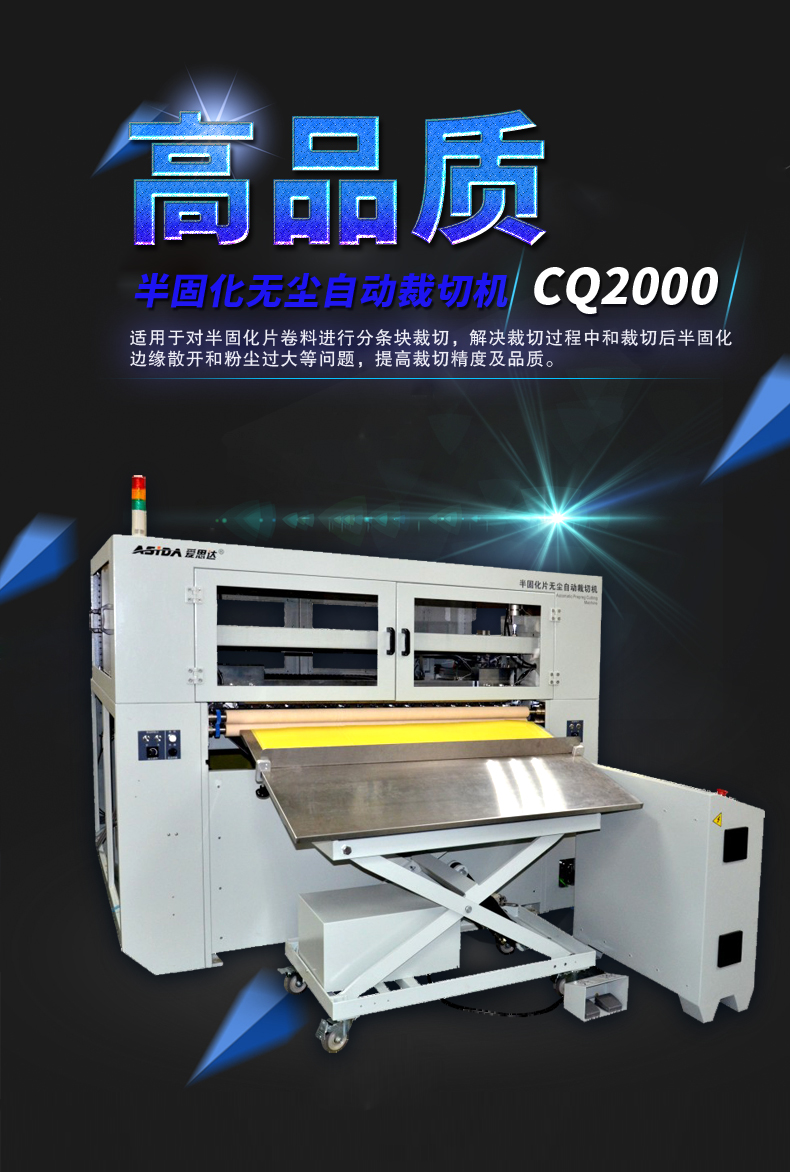

Genuine technology research and development of new products - PP clean cutting machine, to achieve a technological breakthrough and leap, can help you improve the quality of semi-cured film cutting and reduce processing processes to ensure that the physical and mental health, while reflecting the enterprise in the development process Must first people-oriented.

The device uses a radiation heating, short wavelength, penetrating ability, fast heating speed, in the milliseconds to reach the energy of 100% of the output, and according to the process of the need for heating parts to achieve precise positioning, the cutting edge neat, can not afford to powder, not white, not charred, and can automatically cut the edge of the cutting effect. The use of the equipment, can help you achieve technical upgrades, greatly improve the quality of semi-cured film cutting.

PP clean cutting machine, while ensuring the quality, but also to achieve success on environmental issues. Through the infrared heating method of cutting the semi-cured film, to solve the traditional mechanical cutting semi-cured film brought about by dust pollution, glass wire fall and other problems plagued the industry for many years. After the launch of the product, will solve the troubled industry for many years the problem of "dust pollution."

Select PP clean cutting machine, not only can help you will do strong and excellent, but also in line with national and local environmental policy, in the enterprise development on the road ahead of a big step forward.