Solution

Laser Processing Solutions for Copper / Aluminum Alloy Materials

According to the industry information feedback on the market for high anti-material, especially copper, aluminum and its alloys laser cutting demand is increasingly strong. The processing accuracy and processing speed of such materials are getting higher and higher, and the stability of laser cutting is more demanding.

While copper, aluminum and its alloys due to their own characteristics caused by laser cutting is not easy to process. Zhengye laser always adhere to the laser technology research and development and exploration, for customers for copper, aluminum cutting needs, through unremitting efforts to overcome this problem, to provide customers with a comprehensive copper, aluminum precision laser processing solutions.

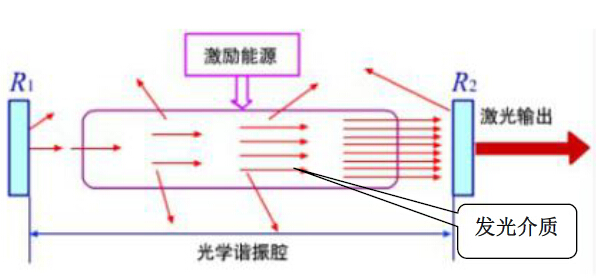

Laser cutting principle

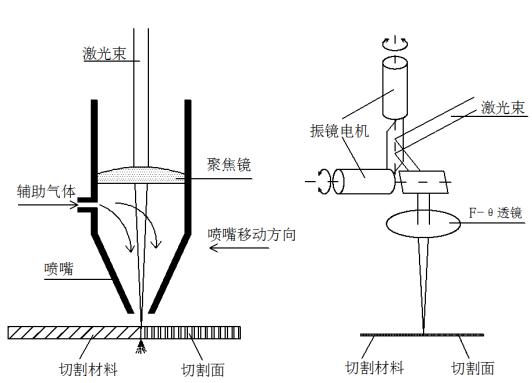

Laser cutting in two ways, one is the way cutting head cutting, the other is the use of laser galvanometer cutting method.

Cutting beam cutting method As shown in Figure 1 A, the laser beam through the focusing lens focused on the workpiece, the high power density laser beam to the workpiece parts of the workpiece quickly melt, vaporize, ablation or reach the ignition, while high-speed auxiliary gas With the beam coaxial blowing, the molten material blowing, laser cutting head and the workpiece to do relative movement, in order to achieve the cutting material. Cutting head cutting method suitable for cutting more than 0.15mm thickness of the material.

Laser beam cutting method as shown in Figure 1 B, the laser beam reflected through the galvanometer, F-θ lens focus, the workpiece in the workpiece, the high power density laser beam to be irradiated part of the workpiece material quickly melt, vaporization , The material through, galvanometer motor drive galvanometer rotation, focusing the spot on the material to move, in order to achieve the workpiece cut. Galvanic cutting method suitable for cutting very thin materials, such as the battery industry with copper foil, aluminum foil.

A cutting head cutting principle B galvanometer cutting principle

Figure 1 laser cutting principle

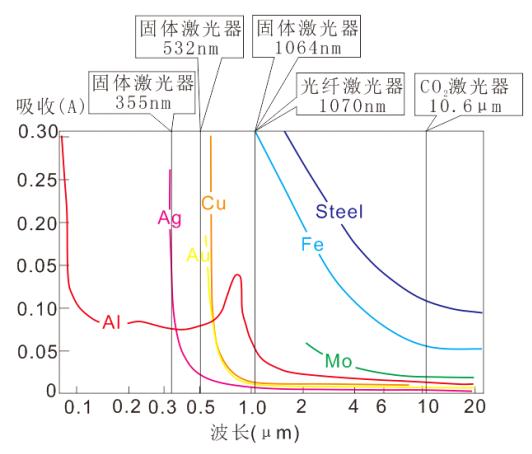

Selection of Processing Laser Wavelength:

Copper and aluminum have the characteristics of high reflectivity of the alloy, the absorption rate of the laser is very low, but also good thermal conductivity. Laser irradiation on such materials, most of the energy will be reflected out, but also quickly will be part of the heat transferred to the surrounding. Resulting in copper, aluminum alloy laser cutting is extremely difficult, or even can not be processed.

Figure 2 shows the absorbance of materials with different wavelengths.

Comparison of the Absorbance of Materials with Different Wavelengths

Through the comparison of the above chart can be found, copper and aluminum materials for 10μm wavelength near the laser absorption rate is very low, so 10.6μm wavelength CO2 laser is not easy to cut such materials. In fact, most of the high-power CO2 laser reflector material is copper, it is the use of copper high reflectivity and high thermal conductivity. If a higher power CO2 laser is used, aluminum and its alloys can be processed, but the processing quality and efficiency are low.

In the 355nm and 532nm wavelength near the laser copper, aluminum absorption rate is very high, but the low power of such lasers, resulting in a low laser cutting speed, can not process thicker materials, if the processing of thin copper foil , Processing effect is good, but the cost is higher.

YAG laser wavelength is 1064nm, copper and aluminum absorption rate is higher than CO2 laser, processing efficiency is high, but the YAG laser needs frequent downtime maintenance, replacement of vulnerable parts, photoelectric conversion efficiency is low, high energy consumption, High maintenance costs.

Fiber laser wavelength of 1070nm, copper and aluminum absorption than CO2 laser high, while fiber laser output power is getting higher and higher, and fiber laser maintenance-free, photoelectric conversion efficiency is high, more energy-efficient, so the fiber laser has become copper, The best choice for laser cutting.